Roadside Revegetation: An Integrated Approach to Establishing Native Plants and Pollinator Habitat

Chapter 5 – Implementation

Table of Contents

Back to top

5.1 INTRODUCTION

A successful revegetation project involves not only good planning but effective implementation of the plan. The Initiation Phase of this report (Chapter 2) described the organizations, decision processes, and technical concepts involved in beginning a roadside revegetation project. The Planning Phase chapter (Chapter 3) outlined the steps in the revegetation planning process resulting in a revegetation plan. This chapter details how the revegetation plan is translated into action at the project site.

The shift from the planning phase to the implementation phase involves a change in approach, and often, personnel. The planning process tends to be orderly and systematic, with the design team able to take an idealized bird’s-eye perspective of how the project might best proceed. In contrast, an implementation approach that is flexible and adaptable can help ensure the objectives of the plan are fulfilled while working with the sometimes-unpredictable nature of construction.

The tasks necessary to successfully implement a revegetation plan are:

- Developing contracts

- Developing an implementation schedule

- Maintaining a materials inventory

- Reviewing plans and coordinating with project engineer

- Assisting in implementing contracts

This chapter provides an overview of the implementation process, providing details on the key factors to consider, including soil and site treatments, obtaining plant materials, installing plant materials, and caring for plants after they have been installed.

5.1.1 DEVELOPING CONTRACTS

Revegetation tasks can be performed in-house, by agency personnel, or through contracts, either performed within the scope of road construction contracts or as separate revegetation contracts. The FHWA and most state DOTs have developed revegetation contract specifications within their standard specifications for construction of roads and bridges. These specifications are designed, in most cases, to be included directly into a road construction contract or revegetation contract. As a designer, it is important that the language in the contract specification accurately describes both the work to be done and the desired outcome, from a revegetation standpoint. Because every revegetation project is different in scope and environmental setting, it is essential that these factors are conveyed in the specification.

For the Designer

Special Provisions or Supplemental Specifications need agency review and approval and the process may take several months. Identification, development, and submittal of these specifications early in the project will reduce delay of final project review approvals for bidding.

Contract specifications detail the how, not the why. To understand the background for a specification for revegetation, it may be useful to review the implementation guides presented in this chapter that pertain to the specific task or topic. With this information, a special provision or supplemental specification based on standard DOT or other agency specifications can be developed to respond to the specifics of the project and environmental surroundings. It may also be helpful to review contract specification examples developed by other agencies. Some revegetation specifications for the FHWA and several state DOT’s can be found in the Native Revegetation Resource Library by selecting “Contract Specifications” under the Report Type search filter.

To evaluate the implementation of contracts, quality assurance standards are defined in the contract specifications. The contractor typically provides monitoring and inspection of these standards to ensure that tasks are carried out as contracted. For example, a hydroseeding contract may have a specification to apply 30 pounds of seeds, 1,000 pounds of wood fiber mulch, and 50 pounds of tackifier per acre. Quality control for this task might be to count the pounds of seeds, wood fiber, and tackifier going into the hydroseeder tank and measure the area to which the mix is applied. This assessment determines if that the rate of materials applied is within quality standards and, if not, alerts the contractor to make appropriate corrections. The written results of these assessments become “as-built” records which can be used by the designer when developing the monitoring report (Section 6.2).

Accurately calculating the contract area is essential in developing contracts. Table 5-1 is an example of how cross sections can be used to determine the contract area. When cross sections are not available, the contract area can be determined from the plan map. In this method, the area is measured and adjustments are made for slope gradient (Table 5-2). A third method is to physically measure the distances in the field.

Table 5-1 | Calculating project area from road plans and cross sections

In this example, cross sections are available for each station. The length of each cross section is measured and recorded in a spreadsheet. The slope length is multiplied by the distance between stations to calculate the area for that station. When all stations areas are calculated, the total contract area is summarized.

Station |

Slope length (m) |

Distance between stations (m) |

Area (m2) |

20+1000 |

3 |

20 |

60 |

20+1020 |

4 |

20 |

80 |

20+1040 |

6 |

20 |

120 |

20+1060 |

7 |

20 |

140 |

20+1080 |

6 |

20 |

120 |

20+1100 |

4 |

20 |

80 |

20+1120 |

2 |

20 |

40 |

Total |

640 |

Acres |

0.16 |

Table 5-2 | Area computations adjusted for slope gradient

When cross sections are not available, the plan map can be used to calculate area. On steeper terrain, the area may need to be adjusted by slope gradient based on the following factors.

Slope (V:H) |

Increase factor |

Percent of increase |

1:1 |

1.41 |

41% |

1:1.5 |

1.20 |

20% |

1:2 |

1.12 |

12% |

1:2.5 |

1.08 |

8% |

1:3 |

1.05 |

5% |

1:4 |

1.03 |

3% |

1:5 |

1.02 |

2% |

The contract specifies the work to be done by the contractor or agency personnel, with clear definitions of roles and schedules.

In general, a contract outlines the following:

- Supplies/services to be provided

- Scope of work (size, schedule, etc.)

- Project location

- Contractor obligations

- Revegetation specialist obligations

- Delivery details (who, how, when, including timelines and deadlines)

- Quality standards

- Contractor quality assurance plan (to be provided by contractor)

- Revegetation specialist quality assurance plan (to be provided by designer who will be inspecting the contractor’s work)

- Price (including bid, unit prices, additive or deductive alternate items)

- Payment method (submission of invoices, approval of work)

- Contractor’s designated representative (more efficient to only coordinate with one person)

- Safety plan

- Other terms and conditions (e.g., what to do in the event of changes)

5.1.2 MAINTAINING SCHEDULES AND MATERIALS INVENTORY

Revegetation contracts can begin up to three years before road construction. For example, it is not uncommon for a seed or plant procurement contract to begin during the planning stage of a road project and span into road construction. In addition, procuring plant materials and implementing mitigating treatments often involve separate schedules with different contractors. To keep these details straight, developing an implementation schedule can be helpful. Timelines are often developed during the planning stages and included in the revegetation plan and these become the basis of an implementation schedule.

Most schedules have interdependent and time-linked tasks. In Figure 5-1, for example, the hydroseeding contract is dependent on the success of the seed increase contract. Before that, the seed increase contract requires wildland seeds to be collected by agency personnel or contractors. The success of the hydroseeding contract rests on the successful execution of two tasks that begin years before the actual seeding.

When creating schedules, it is important to incorporate additional time needed to issue contracts. This is especially crucial when ordering plant materials, which will likely require several years for production.

Material quantities for revegetation tasks change through the life of a road project. For example, a nursery may have succeeded in growing more seedlings for certain species, while producing less of others (due to poor germination, frosts, insects, disease, or other events). For plant material contracts, it is important to stay in touch with the growers to determine if there are any changes to the inventories, and make adjustments to the inventory as needed. Other material quantities that can change are topsoil and shredded wood for mulch.

5.1.3 COORDINATING WITH CONSTRUCTION ENGINEER

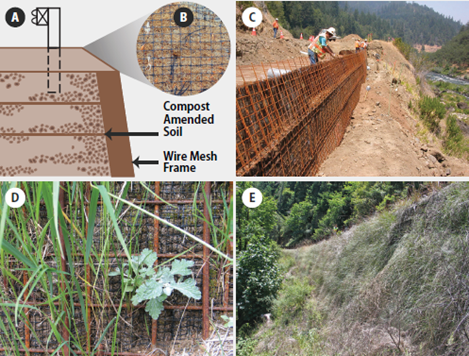

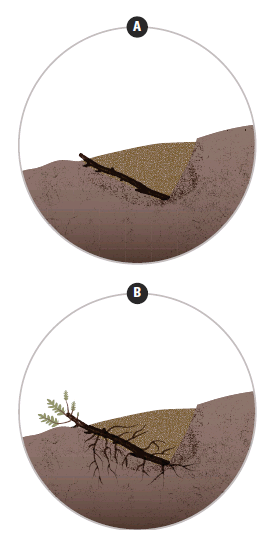

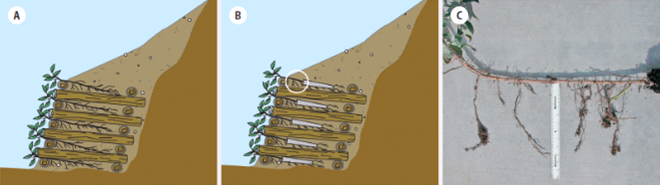

For some road projects, one engineer will oversee the project from inception through its completion. For more complex projects however, the design engineer may hand off the project to a construction engineer member of the project team or from the DOT or agency client to implement. The design engineer, in this case, ensures that tasks outlined in the revegetation plan are designed into the construction documents: plans, specifications, contracts, schedules, materials lists, and coordinated with erosion control plans. The construction engineer implements the road plan with guidance from the design team. Complex revegetation designs, such as vegetated retaining walls, planting pockets, and other biotechnical engineering structures, may require more involvement from the design team.

Before construction begins, a meeting is often scheduled with the construction engineer, road building contractor, and revegetation design team to discuss the revegetation plan. This meeting covers revegetation objectives and outlines the revegetation tasks that need to be coordinated with road construction activities. The construction engineer is made aware of the revegetation treatments and how they are to be implemented. After the initial meeting, the revegetation designer may keep in contact with the construction engineer to help implement the contract specifications. Timely field visits by the designer will help overcome difficulties in integrating revegetation treatments into construction design and schedule.

5.1.4 IMPLEMENTATION GUIDES

Implementation guides are presented in this chapter as background for developing contracts or procedures for revegetation tasks.

The following implementation guides are grouped into four subject areas:

- Section 5.2 Soil and Site Treatments

- Section 5.3 Obtaining Plant Materials

- Section 5.4 Installing Plant Materials

- Section 5.5 Post-Installation Care of Plant Materials

The eight guides in Section 5.2 explain how to improve site and soil conditions prior to the installation of plant materials. These guides cover the mitigating measures most often referenced in Section 3.8.

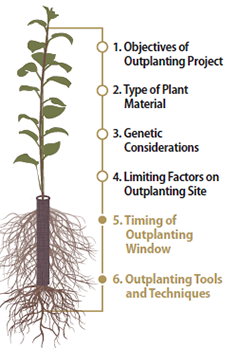

Section 5.3 includes six implementation guides that pertain to collecting and propagating plant materials. These guides describe how to take the species lists developed in Section 3.13, and obtain the desired species in the wild as seed, cuttings, or seedlings. These guides also cover how to increase gathered wild collections at nurseries to ensure that the revegetation project has sufficient quantities of plant materials.

Once plant materials are obtained from the wild or from nurseries, they are installed on the project site. The four guides in Section 5.4 cover the techniques for sowing seed, installing cuttings, and planting seedlings. They also cover how to determine the quality of the plant materials and how to care for them during storage and transportation.

Section 5.5 outlines those practices that occur after the installation of plant materials. These practices help ensure that plants will become established. Practices include protecting seedlings from animal browsing, installing shade cards, irrigating, and installing tree shelters.

Other sources for implementation guides can be found in the Native Revegetation Resource Library by selecting “Implementation Guides” under the Report Type search filter.

Back to top

5.2 SOIL AND SITE TREATMENTS

Most post-construction sites are in poor condition for plant growth and will likely require implementing a set of mitigation measures if good revegetation is expected. The following set of implementation guides cover the common mitigating measures for improving site conditions after construction.

- Fertilizers—Covers how to determine fertilizer quantity, type, and application method.

- Tillage—Describes the common practices of tilling the soil to improve water infiltration and root growing environment.

- Mulches—Seed germination, seedling survival, and surface erosion can be improved through the application of mulches.

- Topsoil—Outlines the removal, storage, and application of topsoil to reconstruct soils on highly disturbed sites. For sites where topsoil is not available or in short supply, organic matter can be applied to improve post-construction soils.

- Organic Matter—Discusses the types of organic matter, how to determine rates, and how it is applied. On some sites where the topsoil has been removed, pH levels may need to be raised to improve plant growth.

- Lime Amendments—Details materials, application methods, and how to determine liming rates.

- Beneficial Microorganisms—Many sites devoid of topsoil need mycorrhizae or nitrogen fixing plants to be introduced. This section covers how to obtain and apply the appropriate sources of these important biological organisms.

- Topographic Enhancements—Revegetation projects can be enhanced by integrating plants into bioengineering structures, water capture features, or planting islands or pockets.

5.2.1 FERTILIZERS

Introduction

Forthe Designer

Base fertilizerrecommendations on soil tests and native plant needs.

Fertilizers are used to bring soil nutrients up to levels essential for establishing and maintaining a desired plant community. When applied within a soil fertility strategy, fertilizer can be a good tool for revegetation but not necessarily needed for every project. In recent years, the use of fertilizers on roadsides for native plant establishment has come under greater public scrutiny and more restrictive water quality laws. Many roads are adjacent to streams, lakes, or residential areas that can be affected by runoff or leaching of inappropriately applied fertilizers. In some instances, fertilizers may not be recommended for establishing native vegetation (see Iowa Roadside Vegetation Management Handbook) because of the potential of encouraging invasive species over native plants. It is important for the designer to learn how to develop fertilizer prescriptions that integrate short- and long-term site fertility goals with water quality and native plant establishment objectives.

It is important to base a soil fertility strategy on the nutrient levels of found in the reference soils when considering the application of topsoil, mulch, compost, wood waste, biosolids, and/or the planting of nitrogen-fixing species. In addition, using commercial fertilizer with other methods of raising nutrient levels, can result in a greater long-term nutrient management of the revegetation project (Section 3.8.4).

This section guides the designer through the steps necessary of developing a fertilizer prescription which is the instructions for ordering and applying fertilizers. They include:

- Determine nutrient thresholds and deficits

- Delineate areas to be fertilized

- Select fertilizer analysis

- Select fertilizer release rates

- Determine application rates

- Determine timing and frequency

- Select application method

Develop Nutrient Thresholds and Determine Deficits

All sites have a minimum, or threshold, level of nutrients that needs to be met for each plant community to become functioning and self-sustaining (Section 3.8.4). Threshold values can be determined by comparing soil tests from several disturbed and undisturbed reference sites (Section 3.5). Finding disturbed reference sites that range from poor success to good success provides a good understanding of nutrient levels and plant response. Based on nutrient values from good and poor revegetation sites, a target nitrogen range can be established between these values. Figure 5-2 provides an example of how a nitrogen threshold value was obtained by evaluating the total soil nitrogen levels from two disturbed reference sites, one considered “fair” revegetation and one considered “poor.” The threshold was set between these two nitrogen levels. Threshold levels represent the minimum level of nutrients needed for a site. In this example, the target nitrogen range for establishing and maintaining the original plant community would be between the minimum nitrogen levels and the nitrogen levels found in the undisturbed reference sites.

To determine whether nutrients are deficient, soil samples are collected from the post-construction sites and tested (Inset 3-2). The nutrient values obtained from these tests are compared against the target ranges to determine if a deficiency exists. By comparing post-construction nutrient values against threshold values, the nutrient deficit can be estimated for each nutrient. Figure 5-3 shows an example of how nitrogen deficits are calculated based on post-construction soil tests. In this example, total soil nitrogen is determined from soil tests. Because soil testing facilities report nutrients in a variety of rates, it is important to convert the rates to percentages then to pounds per acre. Values reported as gr/l, ppm, mg/kg, and ug/g are converted to percentages by multiplying by 10,000. Converting nutrient percentage to lb/ac of the nutrient is done by multiplying percent of nutrient, soil layer thickness, soil bulk density, and fine soil fraction together with a constant (Line E). The result is the pounds of nutrient in an acre of soil on the post-construction site. To determine if the nutrient is deficit, the pounds of nutrients per acre is subtracted from the threshold level (Line F). This value (Line G) represents the nitrogen deficiency and becomes the basis for determining fertilizer prescriptions.

The availability of many nutrients is regulated by soil pH. As discussed in Section 3.8.4, many nutrients are tied up in low pH and high pH soils. Calcium and magnesium are less available at low pH; phosphorus, iron, manganese, boron, zinc, and copper become unavailable in high pH soils. It is important to compare the pH of post-construction soils with reference site soils to determine if the pH is substantially different between the two. If the pH of post-construction soils is different, then taking measures to bring the pH closer to pre-disturbance values is important when developing a nutrient strategy (Section 5.2.6).

Delineate Areas to be Fertilized

Because the post-construction site may differ in soil types and disturbance levels, it is important to delineated areas where fertilizer prescriptions may differ. These differences are usually based on post-construction soil type changes, topsoil salvage, organic amendment additions, or the species and plant material being grown. Areas adjacent to, or that feed into, live water are often delineated and treated with lower rates of fertilizer. Note: If seedlings of shrubs and trees are being planted, spot fertilization may be a more appropriate method than fertilizing the entire area (Inset 5-1).

Inset 5-1 | Spot-fertilizing seedlings

Fertilizing shrub or tree seedlings is done by placing fertilizer in each seedling hole or on the soil surface after each seedling has been planted. This practice has some risks because fertilizers release salts that can damage roots. Studies have shown that placing fertilizers or liming materials in the planting hole or on the soil surface around seedlings at the time of planting can significantly decrease seedling survival, especially on droughty sites (Nursery Technical Cooperative 2004; Jacobs et al 2004; Walker 2002).

These practices may reduce the likelihood of seedling damage:

- Assess the need for fertilizer (do not apply if nutrient levels are adequate)

- Use slow release fertilizers with low salt indexes

- Use low rates of fertilizer if applying at the time of planting

- If applying in seedling hole at planting, use low fertilizer rates and place fertilizer to the side at least 3 inches away from the root system (see figure)

- Preferably broadcast fertilizers on the soil surface after seedlings are well established

When slow-release fertilizers are spread around well-established seedlings (several years after planting), seedlings often respond favorably, especially on highly disturbed sites. Walker (2005) found that slow-release fertilizers applied around the seedlings three years after they were planted increased stem diameter and shoot volume by 143 percent and 104 percent, respectively, over the control when they were measured five years later. In this study, rates of .05 grams of nitrogen per seedling showed the greatest response (at 8 percent nitrogen analysis, this would be over a half pound of bulk slow-release fertilizer per plant).

Figure 5-4 | Example of a fertilizer label for an “all purpose” fertilizer

The three numbers (21-5-20) represent the percentage of nitrogen, phosphorus, and potassium respectively (21%N, 5% P2O5, and 20% K2O). The label may also contain percentages of other nutrients in the fertilizer. Multiplying these percentages (divided by 100) by the pounds of bulk fertilizer applied per acre will give the quantity of each nutrient applied per acre. In this analysis, applying 500 pounds of fertilizer to an acre would deliver 105 lbs N, 25 lbs P2O5, 100 lb K2O, 0.01 lbs B, 0.005 lbs Cu, etc.

Select Fertilizer Analysis

A variety of commercially available fertilizers can be used for fertilizing disturbed sites associated with road construction. The composition, or makeup, of the fertilizer is called the fertilizer analysis. Each container of fertilizer will have a label with a stated “guaranteed analysis” that indicates the percentage of each nutrient contained in the fertilizer (Figure 5-4). The label is the guide for determining which fertilizers to select and how much to apply. Table 5-3 and Table 5-4 provide analysis values for many common fertilizers. Labels can also be obtained from the manufacturer or fertilizer representatives.

Fertilizer labels report nutrients as a percentage. The example label for a 50 pound bag of fertilizer in Figure 5-4 shows 21 percent nitrogen (N), which indicates that 10.5 pounds of material in the bag is made up of nitrogen ( 50 * 21 / 100 = 10.5 ). The bag also contains 0.02 percent boron (B), which indicates that there is 0.01 pounds of boron in the bag. Calculating the amount of phosphorous and potassium is different because the convention for reporting these nutrients is P2O5 and K2O instead of elemental P and K. To convert P2O5 to P, the analysis for P is divided by 2.29. The percentage of P in the bag in Figure 5-4 is actually 2.2 percent, not 5 percent (5.0% / 2.29 = 2.2 ). K2O is divided by 1.21 to obtain 1.6 percent K.

Fertilizers are selected based on whether they contain the nutrients that are deficient on the project site (Section 5.2.1, Develop Nutrient Thresholds and Determine Deficits). For example, if nitrogen, phosphorus, and boron are deficient, only fertilizers that contain these nutrients are considered. Most fertilizers contain more than one nutrient. For example, ammonium sulfate contains nitrogen and sulfur; and triple superphosphate contains phosphorus, sulfur, and calcium. Organic fertilizers contain a range of macro and micronutrients. Fertilizers containing more than one nutrient are used if the nutrients contained in these fertilizers are deficient in post-construction soils. Table 5-2 and Table 5-3 show the combination of nutrients that are available in some commercially available fertilizers.

Table 5-3 | Analysis of common fertilizers

|

Available nutrients (typical percentages) |

| N |

P2O5 |

P |

K2O |

K |

S |

Ca |

Cu |

Fe |

Mn |

Zn |

B |

Mo |

Mg |

| Phosphorus |

Mono-ammonium phosphate |

11 |

48 |

21 |

|

|

24 |

|

|

|

|

|

|

|

|

| Ammonium phosphate |

82 |

|

|

|

|

|

|

|

|

|

|

|

|

|

| Diammonium phosphate |

17 |

47 |

21 |

|

|

|

21 |

|

|

|

|

|

|

|

| Single superphosphate |

19 |

|

|

|

|

12 |

20 |

|

|

|

|

|

|

|

| Triple superphosphate |

|

45 |

20 |

|

|

1 |

13 |

|

|

|

|

|

|

|

| Phosphoric acid |

|

53 |

23 |

|

|

|

|

|

|

|

|

|

|

|

| Dicalcium phosphate |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Soluble potassium phosphate |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Superphosphoric acid |

|

80 |

35 |

|

|

|

|

|

|

|

|

|

|

|

| Potassium |

Potassium chloride |

|

|

|

61 |

50 |

|

|

|

|

|

|

|

|

|

| Potassium nitrate |

13 |

|

|

45 |

37 |

|

|

|

|

|

|

|

|

|

| Potassium sulphate |

|

|

|

51 |

42 |

18 |

|

|

|

|

|

|

|

|

| Micronutrients |

EDTA |

|

|

|

|

|

|

|

10 |

10 |

10 |

10 |

|

|

|

| HEEDTA |

|

|

|

|

|

|

|

6 |

7 |

7 |

9 |

|

|

|

| NTA |

|

|

|

|

|

|

|

|

8 |

|

|

|

|

|

| DTPA |

|

|

|

|

|

|

|

|

10 |

|

|

|

|

|

| EDDHA |

|

|

|

|

|

|

|

|

6 |

|

|

|

|

|

| Granular borax |

|

|

|

|

|

|

|

|

|

|

|

11.3 |

|

|

| Copper sulfate |

|

|

|

|

|

|

|

25 |

|

|

|

|

|

|

| Ferrous sulfate |

|

|

|

|

|

|

|

|

20 |

|

|

|

|

|

| Sodium molybdate |

|

|

|

|

|

|

|

|

|

|

|

|

40 |

|

| Zinc sulfate |

|

|

|

|

|

|

|

|

|

|

36 |

|

|

|

| Zinc chelate |

|

|

|

|

|

|

|

|

|

|

4 |

|

|

|

| Ca & Mg |

Dolomitic limestone |

|

|

|

|

|

|

21 |

|

|

|

|

|

|

11 |

| Magnesium sulfate |

|

|

|

|

|

|

|

|

|

|

|

|

|

43 |

| Gypsum |

|

|

|

|

|

|

23 |

|

|

|

|

|

|

|

| Epsom salt (Epsogrow brand) |

|

|

|

|

|

13 |

|

|

|

|

|

|

|

10 |

Table 5-4 | Estimated nitrogen release rates for commercially available fertilizers

Nutrient release rates are obtained from lab testing but how they release on-site will vary from site to site, depending on temperature, moisture, and whether the fertilizer was placed on the surface or incorporated into the soil. If slow-release fertilizers are broadcast on the soil surface, release rates are slower than if incorporated into the soil where the conditions are better for break down. Arid sites have slower rates of release than sites with high moisture; cold sites take longer to release nutrients than warm sites. First-year nitrogen release rates for fertilizers are identified with an asterisk were adapted from Claassen and Hogan (1998).

Note: Non-asterisk fertilizers were based on best guess estimates.

|

Source |

Available Nutrients |

|

N % |

1st year N release (%) |

% P2 O5 |

% K2 O |

| Ammonium nitrate |

34 |

99 to 100 |

0 |

0 |

| Ammonium phosphate* |

10 |

99 to 100 |

34 |

0 |

| Ammonium sulfate |

21 |

99 to 100 |

0 |

0 |

| Anhydrous ammonia |

82 |

99 to 100 |

0 |

0 |

| Calcium nitrate |

15.5 |

99 to 100 |

0 |

0 |

| Diammonium phosphate |

18 |

99 to 100 |

46 |

0 |

| IBDU |

29 |

95 to 99 |

3 |

10 |

| Potassium nitrate |

13 |

99 to 100 |

0 |

45 |

| Urea |

46 |

99 to 100 |

0 |

0 |

In selecting a fertilizer, the macronutrients (nitrogen, potassium, and phosphorus) that are deficient on a site are considered first because they are the most important for long-term site recovery. If these nutrients are not deficient, chances are that the remaining nutrients are not deficient either. On most highly disturbed sites, nitrogen is most likely to be deficient. Good practice is to consider using this nutrient when approaching fertilizer selection. Table 5-3 lists common nitrogen fertilizers with typical label analysis. It is common to apply more than one fertilizer to meet the various nutrient requirements of the soil. Nutrients other than nitrogen can be supplied by fertilizers shown in Table 5-2.

Organic matter |

45-70% |

Nitrogen |

3-8% |

Phosphorous (P2O5) |

3-8% |

Potassium (K2O) |

<1% |

Sulfur (S) |

0.6-1.3% |

Calcium (Ca) |

1-4% |

Magnesium |

<1% |

Figure 5-5 | Range of organic matter and nutrients in biosolids

Biosolids are rich in nutrients and organic matter, often meeting the requirements to be classified as a fertilizer. This table shows the usual range of organic matter and nutrients by dry weight of material (from Sullivan and others 2007). Biosolids also provide micronutrients, including copper, boron, molybdenum, zinc, and iron.

Biosolids—Biosolids are a nutrient-rich organic material produced from wastewater treatment sewage sludge that are high enough in macronutrients to be considered a fertilizer (Figure 5-5).

When applied to agricultural, forestry, reclamation, and landscaping sites it is a source of nutrients and organic matter. Biosolids improve roadside soils by increasing water-holding capacity, improving soil structure and infiltration, providing slow-release nutrients, and increasing soil biological activity (Sullivan et al 2007). Biosolids are sold as packaged fertilizers from commercial sources or directly in bulk from wastewater treatment centers.

Nitrogen is an important component of biosolids because this nutrient is limiting on most roadsides. Biosolids are basically composed of two forms of nitrogen:

- Ammonium-nitrogen—This form of nitrogen is readily available for plant uptake. If biosolids are surface applied, a portion of ammonium-N is lost as gas. Sprinkler irrigating or tilling biosolids into the soil immediately after application can reduce the amount of nitrogen that is lost (Sullivan et al 2007).

- Organic-nitrogen—Nitrogen in this form is bound to organic matter that has to be digested by soil microorganisms to be released. This process, called N mineralization, takes time. When first applied however, nitrogen release rates are rapid, but level off over the years, to supply a relatively consistent annual supply of nitrogen.

Biosolids are high in other macro nutrients including phosphorus, calcium, magnesium, and sulfur (Figure 5-5). Phosphorus however, is very low and may need to be added depending on the nutrient status of the roadside soils and the biosolids being applied. Phosphorus is present in biosolids at significant quantities yet the availability is around half of a commercial fertilizer because of the predominance of inorganic phosphorus (EPA 1995). Micronutrients, such as boron (B), copper (Cu), iron (Fe), manganese (Mn), molybdenum (Mo), and zinc (Zn) are present in varying amounts but may not be at the ratios found in a well-balanced commercial fertilizer and micronutrient fertilizers may need to be supplemented (EPA 1995).

Some biosolids are stabilized with alkaline materials which can raise the pH of roadside soils. Where soil pH is low, this can be an advantage, and biosolids can be used as a replacement for agricultural limestone (Sullivan et al 2007). However, on high pH soils, the addition of alkaline-stabilized biosolids can be detrimental to plant establishment and plant growth. For these reason, the pH of the roadside soils is important when considering applying an alkaline-stabilized biosolids.

Biosolids are typically applied on roadsides at higher rates than agricultural lands to improve soils and provide nutrients and organic matter capable of supporting native vegetation (EPA 1994). Rates range from 3 to 200 tons/acre but average around 50 tons (EPA 1995). biosolids are relatively light weight and can be half the weight by volume of soil. A 50 tons/acre application rate of biosolids is approximately 0.5-inch thick layer biosolids applied to the surface of a soil. Baxter and Stephan (2011) found that biosolids placed one inch deep on an abandoned timber haul road in Oregon and disked into the soil, was successful in obtaining a high cover of native grass species. On highway right-of-way plots in Rhode Island, Brown and Gorres (2011) found significant improvement of vegetative cover with a 2.0-inch application rate of biosolids compared to a 2.0-inch application of compost. The differences in plant response to compost and biosolids was due to the C:N ratios (biosolids – 7, compost – 64). In this study, biosolids had four times as much total N as the compost. Fava (2015) however, found that at a 1.0 inch application rate, vegetative cover did not differ from the control plots. The differences in findings of these studies point out the importance of knowing the composition of the biosolids and how they respond to the site they are being applied to. Administrative trials, where different rates of biosolids are applied in combination with compost or shredded wood, can will help develop appropriate rates and soil amendments to use to improve the roadside soils.

Select Fertilizer Release Rates

Fertilizers are grouped by how quickly they break down and release nutrients to the soil. They are either fast-release or slow-release. Release rates are important because they determine the rates at which nutrients become available to plants during the year. If nutrients are released during periods when vegetation cannot use them, some will be lost from the site through soil leaching. This is not only a waste of fertilizer but can be source of ground-water pollution.

Fast-Release Fertilizers—Fast-release fertilizers are highly soluble fertilizer salts that dissolve rapidly and move quickly into the soil during rainstorms or snowmelt. The fertilizer label gives an indication of how quickly nutrients are released. Terms such as “soluble,” “available,” or “water soluble” indicate that these nutrients are released relatively quickly. “Ammonium” and “nitrate” forms of nitrogen are also indications of fast-release fertilizers. The fertilizer label shown in Figure 5-4 indicates that the fertilizer contains a fast-release fertilizer and most of the nitrogen would be relatively mobile and available to plant growth within the first growing season. Ammonium nitrate, ammonium sulfate, potassium nitrate, and urea are several examples of fast-release fertilizers.

“Water soluble” or “available” nutrients do not always remain available or soluble after they are applied to the soil. Available forms of phosphorus, for example, react in the soil to form less soluble compounds; potassium gets bound up in soils with moderate to high proportions of clay; and many of the micronutrients (e.g., zinc, copper, and manganese) become unavailable when applied to soils with low pH (Section 3.8.4). Unless soils are sandy or rocky, it can be assumed that many of the nutrients stated as “available,” except for nitrogen and sulfur, will become somewhat immobile once they are applied. Over time, however, these nutrients will become available for plant uptake.

The advantages of fast-release fertilizers are they are relatively inexpensive, easy to handle, immediately available to the plant (especially nitrogen), and can be applied through a range of fertilizer-spreading equipment. Disadvantages are that some nutrients, such as nitrogen, will leach through the soil profile if they are not first taken up by plants or captured by soil microorganisms in the breakdown of carbon.

Nitrates from fast-release fertilizers have been found to leach through sandy soils to depths that are four times the rate of rainfall (Dancer 1975). For example, for sites with annual rainfall of 12 inches, nitrate could move to a depth of 4 feet if it is not taken up by plants or soil organisms. At this depth, nitrogen would be out of range of most establishing root systems.

Because fast-release fertilizers are salts, they have a potential to burn foliage and roots, especially when fertilizers are applied at high concentrations or when applied during dry weather (Section 3.8.4). High concentrations of fast-release fertilizers can also affect germination rates (Figure 5-6) because of the high soluble salt levels (Brooks and Blaser 1964; Carr and Ballard 1979). Salt damage can be reduced by mixing fast-release fertilizers at lower concentrations or by applying them during rainy weather.

Slow-Release Fertilizers—These fertilizers are designed to release nutrients at a much slower rate. To be labeled slow-release fertilizer, some states specify the amount of nitrogen to be in a slow-release form. Forms of nitrogen shown on the label as “slowly available” or “water-insoluble” are good indicators that a fertilizer is in a slow-release form. The advantages of using slow-release fertilizers are as follows:

- Nutrients are supplied at a time when plants are potentially growing

- Less frequent applications

- Less potential for leaching into ground water

- Less potential to cause salt injury

The disadvantages are that many slow-release fertilizers are bulky, cost more to purchase and apply, and are limited by the type of fertilizer application equipment that can be used. Nevertheless, slow-release fertilizers have greater applicability for revegetating disturbed sites than fast-release fertilizers.

Organic slow-release fertilizers—These fertilizers come in either organic or inorganic forms. Organic fertilizers include animal manures (e.g. chicken, steer, and cow), bone meal, fish emulsion, composted sewage sludge (biosolids), and yard waste. Unprocessed organic fertilizers are hard to apply to roadside projects because they are bulky and high in moisture content. Many commercially available organic fertilizers have been processed to remove most of the water, which makes them easier to apply with most fertilizer-spreading equipment. For a good discussion on organic fertilizers, see Landis (2011).

The agents responsible for release of nutrients from organic fertilizers are decomposing soil bacteria. When soil bacteria are active, the release of nutrients is high; when dormant, the rate is low. The release of nutrients is therefore a function of moisture and temperature, which governs the rate of bacterial growth. Warm temperatures and high moisture, conditions conducive to plant growth, are also favorable for the breakdown of organic fertilizers. Because of this, the release of nutrients from the decomposition of organic fertilizers often coincides with the period when plants are growing (spring and fall) and the need for nutrients is greatest. The nutrient-release mechanism of slow-release organic fertilizers reduces the risk that highly mobile nutrients, such as nitrogen, will be released in the winter when plants are incapable of absorbing them and the potential for leaching is greatest.

Inorganic forms of slow-release fertilizers were developed for the horticulture and landscape industries where they have become an effective method of fertilizing nursery plants. These are expensive forms of fertilizer and have not been tested on roadside revegetation conditions. Nevertheless, they potentially have applicability for some native revegetation projects.

Inorganic slow-release fertilizers—These fertilizers include ureaform, nitroform, isobutylidene diurea (IBDU), sulfur-coated urea, and polymer-coated nitrogen, phosphorus, and potassium. These fertilizers have varying mechanisms for nutrient release. Fertilizer granules coated with materials that release nutrients only during warm, moist conditions ensure that nutrients are available during the period when plants are most likely to be growing. These coatings include sulfur (e.g., sulfur-coated urea) and polymers. Each fertilizer has its own formulated nutrient release rate, which varies from 3 months to 18 months. Release rates are available from the manufacturers for most inorganic, slow-release fertilizers. However, it is noteworthy that these rates were developed for 70° F soil temperatures (Rose 2002), which are higher than soil temperatures in the western United States during the spring and fall when roots and foliage are growing. If roadside soils are colder than 70° F, nutrient release will take longer than what the manufacturer states.

Determine Fertilizer Application Rates

Fertilizer rates are determined for each deficient nutrient, as shown in Figure 5-7. The calculation in this example was done to eliminate a nitrogen deficit of 769 lb/ac. Using a slow-release fertilizer with 8 percent nitrogen, the amount of bulk fertilizer necessary to bring nitrogen levels to minimum targets is 9,613 lb/ac ( 769 * 100 / 8 = 9,613 ), which is a high rate of fertilizer to apply. With a release rate of approximately 40 percent the first year, 308 lbs N/ac would be available, far more than the establishing plant community could absorb. Alternatively, using a fast-release fertilizer with higher nitrogen analysis, such as ammonium nitrate (33 percent N), would reduce the amount of bulk fertilizer to 2,330 lbs/ac ( 769 * 100 / 33 = 2,330 ). While there would be less weight with this more concentrated fertilizer, this is considered a dangerously high application rate because all of the nitrogen would be released in the first year resulting in a much greater potential that high amounts of nitrates are leached through the soil into the ground water and a higher risk that elevated salt levels would be toxic to plant growth. This example illustrates the difficulty in developing fertilizer prescriptions to meet long-term nutrient targets. How does the designer develop a fertilizer strategy to meet short-term and long-term plant needs without over- or under-fertilizing?

The approach presented in this section is based on meeting short-term nutrient needs of the establishing plant community while building a long-term nutrient capital. For example, applying fertilizer at the time of seeding requires very low rates of available nitrogen to meet the first-year needs of the establishing vegetation. Any extra fertilizer has the potential of being wasted. As the vegetation develops over the next few years, the ability of the plant community to take up more available nutrients increases. A strategy of applying low amounts of fertilizer the first year, followed up with higher rates in later years would supply the levels of nutrients needed for a developing plant communities without wasting fertilizers. This practice, however, is seldom employed in roadside revegetation projects. In fact, the typical fertilizer practice does just the opposite—high rates of fertilizers are applied with the seeds to a site that has no vegetation that could utilize the available nutrients. There is no return to the site in later years to assess whether additional applications of fertilizers might be essential for vegetation maintenance or growth. The approach advocated in this section is applying the appropriate mix of fertilizers to meet the annual needs of the vegetation while building long-term nutrient capital until the plant community is self-sustaining. This approach may require fertilizer application over a period of several years.

Because nitrogen is the key nutrient in establishing plant communities, this approach involves established short- and long-term nitrogen requirements of the plant community. Calculating long-term nitrogen target is addressed in Section 5.2.1 (see Develop Nutrient Thresholds and Determine Deficits). Short-term targets are more difficult to set because they change over time. They are governed by the following:

- Soil type

- Carbon-to-Nitrogen ratio (C:N ratio)

- Climate

- Amount of vegetative cover

- Type of vegetation

- Age of vegetation

Some general guides can be helpful in setting short-term nutrient targets for available nitrogen. Applying fertilizer at the time of sowing, for example, requires very low rates of available N because vegetation is not there to utilize it. Rates range from no fertilizer to up to 25 lb/ac of N when applying fertilizer with seeds. During plant establishment, available N can range from 25 to 50 lb/ac (Munshower 1994: Claassen and Hogan 1998). After plant establishment, rates can be increased to account for increased plant utilization above this amount. These suggested rates are adjusted upward on sites where high C:N soil amendments, such as shredded wood or straw, have been incorporated into the soil to compensate for nitrogen tie-up. Calculating precise rates of supplemental nitrogen for incorporated organic amendments is very difficult. In nursery settings, rates of over 100 pounds of supplemental nitrogen have been recommended for incorporated straw, sawdust, and other high C:N materials (Rose et al 1995). However, applying supplemental rates on highly disturbed sites is to be done with caution, utilizing trials where possible to determine more precise fertilizer rates. Periodic soil analysis can provide the designer with a better understanding of the soil nitrogen status. To keep testing costs low, only available nitrogen and total nitrogen need to be tested (Section 3.8.4, see Mitigating for Lack of Topsoil).

In determining how much fertilizer to apply, it is important to estimate how much nitrogen will be available the first and second years. Manufacturers have this information for most inorganic slow-release fertilizers. Claassen and Hogan (1998) have also performed tests on some slow-release organic fertilizers (Table 5-4). Release rate determinations are performed in the laboratory but the actual release rates will vary in the field by soil type and climate. In the example described in Figure 5-7, the first-year release rate of nitrogen from the slow-release organic fertilizer was estimated at 40 percent. This was a guess based on the manufacturer’s estimates of 55 percent release, but because it was being applied to a semi-arid site where decomposition of the fertilizer would be slow, the rate was dropped to 40 percent (Line D). If 40 percent of the nitrogen became available the first year, 60 percent would remain for the following years (Line E). At this release rate, 308 lb/ac of nitrogen would become available the first year after application (Line F). While this is an extremely high rate, consider the application of ammonium nitrate at 100 percent first year release, which would supply 769 lb/ac (Line A) of immediately available nitrogen. Recalculating fertilizer rates using a more realistic rate of 50 lb/ac available nitrogen needed the first year after application (Line F), bulk fertilizer application rates would be 1,563 lb/ac (Line H). At this new rate, the site would have sufficient first- and second-year supplies of nitrogen but lack adequate nitrogen the following years. The remaining deficit to meet long-term nitrogen targets would be approximately 644 lb/ac, which could be supplied through later applications of fertilizer or other carriers of nitrogen (topsoil, compost, biosolids, wood waste, mulch, and nitrogen-fixing plants). In this example, nutrient strategy would be built upon treatments that would increase long-term nitrogen capital.

The process of calculating fertilizer application rates in Figure 5-7 can be used for other deficient nutrients, however, understanding the availability of these nutrients is problematic. Many nutrients become fixed in the soils and their availability is dependent on highly variable factors such as soil texture, pH, and placement in the soil. It is a reasonable assumption that unless the soils are sandy or very rocky, that all nutrients, aside from nitrate or ammonium forms of nitrogen, are relatively unavailable the first year after application. With time, however, they will slowly become available.

Determine Timing and Frequency

The primary reason to fertilize is to supply nutrients during periods when plants can take them up for growth. The demand for nutrients changes throughout the year depending on the physiological state of each plant. In nursery settings, fertilizers are adjusted throughout the year at rates and formulations that correspond to plant requirements. While that capability is not possible in roadside environments, fertilizers can be used more wisely by applying an understanding of how the assortment of fertilizers function in meeting the nutrient requirements of plant communities. At least two plant growth phases are important in the timing of fertilizer application: (1) seed germination and plant establishment and

(2) post-plant establishment.

Seed Germination and Plant Establishment Phase—Traditionally, fast-release fertilizers have often been applied at high rates in the fall in the northern United States during the seed-sowing operation. This practice is a quick and easy way to apply fertilizers. However, the timing can result in ineffective and wasteful use of fertilizers (Figure 5-8B) (Dancer 1975). In addition, application of fast-release fertilizers at this time can potentially pollute water sources. Slow-release fertilizers are more appropriate for seed sowing in the fall because much of the fertilizer, but not all, is expected to release nutrients the spring, not in the fall or winter (Figure 5-8D).

Perennial grasses and forbs do not require high levels of nitrogen for germination and early establishment (Reeder and Sabey 1987). In fact, an elevated level of available nitrogen can be a problem because it encourages the rapid establishment and growth of annual weed species over slower-growing perennial grass and forbs (McLendon and Redente 1992; Claassen and Marler 1998). It is important to calculate fertilizer quantities based on the plant requirements over time (Section 5.2.1, see Determine Fertilizer Application Rates).

One strategy is to apply little or no fertilizer during sowing and wait until seeds have germinated and grown into small seedlings before fertilizers are applied (Figure 5-8C). This strategy ensures that nutrients are available when the seedlings actually need them, not before. Fertilizers applied as slow-release form are preferred because they have less potential for causing salt damage when applied over emerging seedlings. Another strategy is to wait until the following fall (Figure 5-8E) or spring (Figure 5-8F) of the second year to fertilize.

Post-Establishment—Once vegetation is established (one or two years after sowing), fertilizers may be applied at higher rates with the assurance that nutrients will be taken up by the plants. It is important that the application rates are based on nutrient levels of the soil and the needs of the native plant species. On fertile soils, there may be no need to fertilize, whereas on soils without topsoil or low in organic matter, a post-establishment fertilizer application may be needed.

Slow- and fast-release fertilizers can be combined to provide short- and long-term nutrient requirements (Figure 5-8E and F). Spring applications of fast-release fertilizers are more effective than fall application because of the higher nutrient requirements of growing plants during that period (Figure 5-8F). In addition, spring applications may pose less risk of damaging vegetation through fertilizer salts on sites where precipitation in the spring is frequent enough to wash fertilizers from the foliage. The conductivity of a fertilizer solution being applied over existing vegetation can be measured with a conductivity meter to avoid salt damage (Section 3.8.4). If rates exceed 3,500 mS/cm, then diluting the solution or applying the fertilizer during rainy weather is advised. Fertilizer rates can also be adjusted based on the salt tolerance of a plant species (see ERA).

Select Fertilizer Application Method

Because nutrients have varying degrees of mobility (nitrogen is highly mobile; phosphorus and many micronutrients are relatively immobile), how fertilizers are applied will determine how accessible nutrients are to the root systems of establishing vegetation. If nutrients are highly mobile, the easiest and least expensive method is broadcasting fertilizer to the soil surface to allow rainfall or snowmelt to release and move nutrients into the soil. A more difficult, yet more effective application method for immobile nutrients is to incorporate, or mix, fertilizers into the soil so fertilizer granules are uniformly distributed and accessible by root systems.

Broadcast Fertilizer Application—For fertilizers with highly mobile nutrients, such as nitrogen and sulfur, broadcast application on the soil surface is an appropriate practice. Broadcast fertilizer application is less effective, however, for immobile nutrients. These nutrients often become immobilized at the soil surface and are very slow to move into the rooting zone where they can be accessed. Depending on soil characteristics, such as pH and clay content, some immobile nutrients will take years to move only a few inches from the point of fertilizer placement.

A variety of dry fertilizer spreaders are available, from hand-operated to tractor-mounted. Most equipment is limited to moderate slope gradients (less than 1V:2H). With all forms of spreaders, consider calibrating them before they are used to ensure that the correct rates are being applied.

Hydroseeding equipment can be used to apply fertilizer in the same operation with seeds, tackifiers, and hydromulch (Section 5.4.2). This equipment can also be used solely to apply fertilizers, especially after vegetation has become established. A great advantage to using hydroseeding equipment is that it can uniformly spread fertilizers on steep slopes and a variety of topographies. In addition, a combination of fertilizers can be easily mixed in the hydroseeder tank and applied uniformly at relatively even proportions. This is especially useful for applying small quantities of fertilizer, such as micronutrients, which are difficult to spread evenly over large areas.

Fertilizer Incorporation—It is important that nutrients that are deficient and have low mobility be incorporated into the soil prior to sowing or planting. Incorporation is possible on gentle slopes but becomes very difficult with increasing slope gradients because of equipment limitations or slope stability. On sites where fertilizers containing immobile nutrients cannot be incorporated, an alternative is to create roughened soil surfaces (Section 5.2.2) prior to fertilizer application. Broadcast fertilizers will accumulate in the depressions of the surface. As soil gradually moves into the depressions over time through erosion (water, wind, or surface ravel), the broadcast fertilizers will become covered with soil. When this happens, immobile nutrients are accessible by roots and nutrient uptake is possible. Surface roughening also reduces the potential for fertilizers to move off-slope through erosion.

Some agricultural spreaders, called fertilizer banders or injectors, are designed to place fertilizer, or other soil amendments including mycorrhizae, at varying depths in the soil. Usually this equipment has a ripping shank or tine that loosens the soil, followed by a tube that drops the fertilizer, and coulters or rollers that close the furrow. As the bander is pulled through the soil, a line, or band, of fertilizer is created. Sowing and banding are often combined in one piece of equipment and applied at the same time. Fertilizer banders were developed for agricultural use and are limited by rock content and slope gradients, however, there are injectors that have been developed for wildland conditions (St. John 1995).

The most common approach to incorporating fertilizer is accomplished in two operations, broadcasting fertilizer on the soil surface and tilling it into the soil. In this approach, hydroseeders and broadcast fertilizer spreaders are used to apply fertilizers evenly over the soil, then the fertilizer is incorporated using tillage equipment outlined in Section 5.2.2.

5.2.2 TILLAGE

Introduction

Tillage is defined in this section as any mechanical action applied to the soil for the purposes of long-term control of soil erosion, reestablishment of native plant communities, and improve soil function. Most tillage equipment was developed for agricultural soils and has limited applicability for steep, rocky sites typically encountered in revegetation. This section describes the agricultural equipment that can be used for revegetating roadsides, as well as equipment specifically developed for extreme site conditions.

Among the reasons to use tillage in a revegetation project is to shatter compacted soils, incorporate soil amendments, and roughen soil surfaces. These objectives often overlap. For example, incorporating organic matter also loosens compacted soils and roughens soil surfaces. Identifying the objectives for the project will lead to selecting and effectively using the appropriate equipment to achieve the desired soil conditions (Table 5-5).

Shatter Compacted Soils

One of the primary purposes for tilling is to loosen compacted soils. When performed correctly, tillage can increase porosity in the rooting zone, increase infiltration rates, and increase surface roughness. For revegetation work associated with road construction and road obliteration, tillage to break up deep compaction is important for reestablishing plant communities. Shattering compaction at depths of at least 2 feet is essential for the healthy growth of most perennial plant species. Without this measure, it may take decades for deep compaction to recover its original bulk density (Wert and Thomas 1981; Froehlich et al 1983). In a review of tillage projects on rangeland soils, Gifford (1975) found that deep tillage greatly reduced runoff, while shallow tillage had little effect. Still, tillage alone may not return a soil to its original bulk density or hydrologic function, nor will the effects of tillage last indefinitely, especially in non-cohesive soils (Figure 5-9) (Onstad et al 1984). Many factors affect the return to bulk densities and infiltration rates typical of undisturbed reference sites. These include the type of tillage equipment used, tillage depth, soil moisture during tillage, soil texture, presence of topsoil, and organic matter content.

Table 5-5 | Types of tillage and equipment

The appropriate tillage equipment for the project depends on project objectives.

Objectives |

Shattering |

Incorporating |

Imprinting |

Rippers and subsoilers |

Disks, plows, excavator attachments |

Dixon imprinter, excavator attachments, trackwalking |

Loosen compacted soil |

Good |

Good |

Poor |

Incorporate amendments |

Poor |

Good |

Poor |

Roughen surface |

Good |

Good |

Good |

There are two fundamentally different equipment designs for reducing compaction. One design lifts and drops soil in place, shattering compacted soil in the process. This type of equipment includes rock rippers, subsoilers, and “winged” subsoilers. The second design churns and mixes the soil. Equipment that falls into this category includes disk harrows, plows, spaders, and attachments to excavators. This type of equipment can also incorporate soil amendments, such as organic matter or fertilizers, in the same operation, as described in Section 5.2.2 (see Incorporate Soil Amendments).

The terms “subsoiling” and “ripping” are used interchangeably to describe soil-shattering operations. Soil shattering involves pulling one tooth, or a set of teeth, at various depths through the soil to break up compaction created by equipment traffic. The rock ripper is a common tool found on most construction sites. When used to break up compaction, one or two large ripper tines are typically pulled behind a large bulldozer at 1 to 3-foot soil depths. While this equipment will break up compaction in portions of the soil where the ripper tines have been dragged, it does not effectively fracture the compacted soil between the ripper tine paths (Andrus and Froehlich 1983). The effectiveness of rippers can be increased by multiple passes through the soil or by adding tines to the toolbar. Even on small machines, up to five tiplan es can be added to increase soil shatter.

Figure 5-10 | Winged subsoiler

Soil shattering becomes more effective when wings are mounted on subsoil tines. This equipment is called a winged subsoiler. Photo credit: Brent Roath

Rippers have also been adapted to increase soil lift between tine paths by welding wide metal wings to the bottom of each tine. These wings are angled upwards so the soil between the tines has greater lift, and therefore greater shatter when the soil drops behind the wing. When two or more tines are placed together on a toolbar, they work in tandem to more effectively break up compaction. The resulting equipment is called a “winged” subsoiler (Figure 5-10). Andrus and Froehlich (1983) found that the winged subsoiler was a far more effective tool for breaking up compaction. This equipment fractured over 80 percent of the compaction in several operational tests, as compared to 18 to 43 percent for rock rippers and 38 percent for brush rakes. However, winged subsoilers are not practical in all soils, especially those with high rock fragments, buried wood, or slopes greater than 3H:1V gradients.

Achieving good shatter at deeper soil depths means that tillage equipment be adjusted for site-specific soil conditions, especially soil texture, soil moisture, and large rock content. Tines will slice through the soil, causing very little soil shatter, if soils are too moist during ripping. Subsoiling when soils are extremely dry can bring up large blocks of soils, especially when the soils are high in clays (cohesive soils).

It is important the winged subsoiler and rock ripper be adjusted to meet the soil conditions of the site. Making the proper adjustments can lead to greater shatter and more efficient use of tractor equipment. These adjustments include the following:

- Tine depth

- Tine spacing

- Number of tines

- Wing width and angle (for winged subsoiler)

Inset 5-2 | Contract specifications for a winged subsoiler

A winged subsoiler consists of a self-drafting, winged subsoiler on a dolly mount, sized for use with a D-7 tractor. The unit consists of three-winged ripper tines capable of extending 12 to 34 inches below the draw bar. Wings are usually at least 20 inches wide with a 2-inch lift of the wings from horizontal. Tines have an individual tripping mechanism that automatically resets; tine spacing is adjustable, and individual tines removable. Various wing patterns are available and easily interchangeable. Good practice is to have an implement capable of achieving maximum fracture of compacted soils (minimum 24 inches) in one pass (adapted from Wenatchee National Forest contract specifications).

For optimum shatter, the depth of the tines is adjusted based on the soil properties and moisture conditions. The tines are adjusted to be above a “critical depth,” the point below which soils will not shatter effectively (Figure 5-11B). The critical depth changes for soil type and tine configuration. Soils high in clays with high soil moisture have shallower critical depths (Andrus and Froehlich 1983).

The closer the spacing of tines, the greater the shattering. The more tines that are placed on a toolbar, the more area of soil that can be shattered. However, where large rocks, slash, and roots are present, closely spaced tines will drag these materials out of the ground. Three to five tines are typically used for most soil types. Wing size, angle, and shape of the tines all play a role in breaking up compaction (refer to Inset 5-2 for specifications for winged subsoiler).

Typical settings for rock ripper and winged subsoiler equipment configurations are shown in Table 5-6. These are suggested settings to be applied after first monitoring the results of the equipment on the project soils. The most direct method for monitoring soil shatter is to measure the depth to the compacted soil with a soil penetrometer or shovel (Section 3.8.2, see Soil Structure). Immediately after a pass is made with the tillage equipment, the shovel or penetrometer is pushed into the soil and the depth to resistance (the compacted layer) is recorded. Measurements are taken every 6 inches across a small transect perpendicular to the direction of the tractor and spanning the width of the tillage disturbance. Plotting the depths to compaction on graph paper provides a cross-section of the shattering pattern (Figure 5-11 is an example of plotting soil shatter). If the shattering pattern is inadequate, adjustments can be made to the tine depth, tine spacing, and angle of the wing. If these adjustments fail to increase soil shatter, a second and perhaps third pass by the ripper or winged subsoiler can be considered. Successive passes made at 45 to 90 degrees angles from the first pass achieves the greatest benefit. Most soil-shattering equipment is attached to the tractor toolbar and is limited to slope gradients of 3H:1V or less. Subsoilers and rippers are best used for projects that consist of gentle terrain or obliterated road sections.

Table 5-6 | Recommended design features for some tillage equipment

Modified after Andrus and Froehlich 1983; Froehlich and Miles 1984

Item |

Implement feature |

Recommended design |

|

Disk harrow |

Disk diameter |

40-50 in. |

Number of disks |

6-12 |

Average disk weight |

>1,800 lbs |

Disk arrangement |

Offset gangs, independent disks |

Max slope (cross slope travel) |

<5:1 H:V |

Max slope (down slope travel) |

5:1 H:V |

Brush blade |

Tine spacing |

22-26 in. |

Tine depth |

<20 in. |

Max slope (cross slope travel) |

<5:1 H:V |

Max slope (down slope travel) |

3:1 H:V |

|

Rock rippers |

Tine spacing |

24-30 in. (one pass) 40-48 in. (two passes) |

Ripping depth |

20-24 in. |

Number of tines |

5 (one pass)

3 (two passes) |

Max slope (cross slope travel) |

<5:1 H:V |

Max slope (down slope travel) |

2.5:1 H:V |

|

Wings of subsoilers |

Ripping depth |

18-22 in. |

Number of tines |

3-4 |

Tine spacing |

30-40 in. |

Wing width |

12-24 in. |

Wing angle |

10-60° |

Max slope (cross slope travel) |

<5:1 H:V |

Max slope (down slope travel) |

2.5:1 H:V |

The excavator is good piece of equipment on steeper slopes where its arm can reach 35 feet up and down slope and decompact targeted areas of compacted soil. In this operation, the bucket of the excavator is placed several feet into the soil, lifted and dropped in place (Figure 5-12). Special attachments, such as the “subsoiling grapple rake” have been developed for the excavator that can decompact, incorporate, and remove rock and slash in the same operation (Archuleta and Baxter 2008).

A general rule for tillage is to operate equipment on the contour to reduce the potential of water concentrating in the paths of the furrows and creating soil erosion and slope stability problems. This is especially important on steeper slopes where the potential for soil erosion and slope instability are greater. If several passes are made, it is important to make the last pass on the contour.

It is also important to consider that when cuts and fills are tilled, soil strength is reduced and the soils are less resistant to concentrated water. Improper road or slope drainage may result in rills and gullies on tilled soils, a situation that is less likely to occur when soils are compact. Therefore, on slopes that have been tilled, it is important that road water is directed away from fill slopes at least until vegetation has stabilized the slopes. It is important to discuss any tillage operation on slopes adjacent to roadways with the design engineer to ensure that slope stability and road objectives are not compromised.

Incorporate Soil Amendments

Tilling is used to incorporate fertilizers, organic matter, lime, and other amendments that are placed on the soil surface and evenly distributed in the soil. Tilling with these objectives involves equipment that mixes soil, such as plows, tillers, disks, chisels, and soil spaders. These types of equipment are tractor-drawn and limited to gentle slope gradients (5H:1V or greater) and soils low in rock fragments. They are not designed to break up deep compaction. Under most disturbed soil conditions, the best that can be expected from this equipment is tillage to a depth of 8 inches.

The excavator is also another tool for incorporating soil amendments. It has the advantage over tractor based equipment in that it can incorporate soil amendments several feet into the soil. It can also be used to move topsoil or organic matter to concentrated locations to create mounds or planting islands (Section 5.2.8). When islands are created for deep-rooted species, such as shrubs and trees, soil amendments are applied to the surface of the soil and incorporated several feet deep. Care taken on sites where natural soil horizons or soil layers have been placed (e.g., topsoil, liter, and duff) can help prevent mixing these layers together.

Rippers and subsoilers are less effective in incorporating materials such as fertilizers or organic matter into the soil. Nevertheless, spreading mulch on the soil surface prior to ripping or sub- soiling usually incorporates enough organic matter into the soil surface to enhance infiltration rates (Luce 1997). In the same manner, fertilizers applied to the soil surface, especially those containing immobile nutrients, will be mixed into the top several inches of soil and made available to surface roots.

Roughen Soil Surfaces

Tilling is often done to roughen the soil surface for erosion control and to create a more optimum seedbed (Section 3.8.5, see Surface Roughness). The micro-topography of a roughened surface consists of discontinuous ridges and valleys where the valleys become the catch basins for seeds and surface runoff. Seeds have greater opportunities to germinate and become established in the micro-valleys because of increased moisture, higher humidity, protection from the wind, and shelter from the sun. Surface roughening is a side benefit of the incorporating and shattering operations described in Section 5.2.2 (see Shatter Compacted Soils) and Section 5.2.2 (see Incorporate Soil Amendments).

Roughening is also accomplished by either scarifying or imprinting operations. Scarification is the shallow loosening of the soil surface using brush blades, harrows, chains, disks, and chisels. It does not loosen compacted soils below the surface. Because it only loosens the soil surface several inches, the benefits for revegetation are only seen during seed germination and early seedling establishment. Once root systems hit a compacted layer, which is typically present several inches below the surface, growth is curtailed.

Figure 5-13 | Trackwalking compacts soils

Trackwalking creates imprints on the soil surface, but will also compact surface and subsurface soils.

Photo credit: David Steinfeld

Imprinting is a form of surface tillage that leaves the soil with a pattern of ridges and valleys. The equipment applies a downward compressive force to a metal mold, leaving an impression on the soil surface. Specialized imprinters have been developed for rangeland restoration. For example, the “Dixon” imprinter was developed to restore perennial grasses for rangelands in Arizona and other arid states. It consists of a roller with large angular metal “teeth” that is pulled behind a tractor. The imprinter creates a pattern of V-shaped troughs, 4 to 7 inches deep, encompassing approximately 1 ft2 area (Dixon and Carr 2001a, 2001b). This equipment also has a set of ripping shanks attached to the tractor that shatters deeper compaction before imprinting.

A common practice of imprinting is trackwalking (Figure 5-13). In this operation, a tractor is “walked” up and down cut and fill slopes, leaving a pattern of tractor cleat imprints on the soil surface, parallel to the slope contour, no deeper than several inches. These imprints are substantially shallower than those created by the Dixon imprinter, with less longevity. Because heavy equipment is used, trackwalking can compact soils. Compaction is not often considered when selecting trackwalking practices because soils of most roadside construction sites are already very compacted and trackwalking is unlikely to significantly increase compaction. This is one reason why trackwalking has been considered beneficial for erosion control and revegetation because it can create a somewhat better “short-term” growing environment and reduce surface erosion and sedimentation on very poor sites.

If the last operation on a construction site is to subsoil or rip soils 1.5 to 2 feet deep and leave the soil in a decompacted condition prior to revegetation, trackwalking would be more detrimental than beneficial on most soils in the long-term. The weight of the tractor used to create imprints would compact the tilled soil leaving the surface smoother (less rough) than if left alone. As noted before (Chapter 3), compaction reduces infiltration and increases runoff; therefore, trackwalking has the potential to increase in soil erosion. Rainfall simulation tests can be run on sites near the construction project that have been trackwalked and compared with those that have been left in an uncompacted state to determine the effects on runoff and soil erosion (Hogan et al 2007).

Figure 5-14 | Soil imprinting with modified excavator bucket

An alternative form of imprinting road cuts and fills that does not compact soils is welding angle iron onto the bucket of an excavator. As the excavator pulls top- soil into place and contours the slope, it presses the face of the bucket into the soil surface to form surface imprints.

Photo credit: David Steinfeld

An alternative to trackwalking is the use of the bucket of an excavator to pack and imprint the soil surface. Different patterns of steel “teeth” can be welded on the face of the bucket to achieve the desired surface micro-relief. Figure 5-14 shows an excavator bucket, with four strips of angle iron welded to its face, to create a pattern of 3-inch-deep impressions. The excavator, in this example, moves topsoil to the site, shapes the cut and fill slopes, and imprints the surface, all with one operation.

5.2.3 MULCHES

Introduction

Mulch is defined as a protective material placed on the soil surface to prevent evaporation, moderate surface temperatures, prevent weed establishment, enrich the soil, and reduce erosion. Mulches, therefore, have many functions or roles in the recovery of native vegetation to a disturbed site. Confusion often arises around the use of mulches on revegetation projects unless the reasons for using them are clearly defined. In this discussion, mulches are grouped into four uses based on the revegetation objectives:

- Seed Covering

- Seedling Mulch

- Soil Improvement

- Seed Supply

For most projects, mulches are used to meet more than one objective but this is problematic when the methods for achieving more than one objectives are not compatible. For example, erosion-control products and practices that are effective for controlling surface erosion are not always optimal for establishing vegetation. For this reason, it is important to understand the objectives for mulching when selecting mulch types and application methods.